Lean more

Fit flexibly! High SN Ratio and narrow dead band! Cartridge type probe!

We started selling the new model of ultrasonic soft probe2015/01/05

Japan Probe Co, Ltd developed the new model of ultrasonic soft probe, and we start selling it on 5th January, 2015.

*Problems of conventional ultrasonic probe

Conventional soft probe has the following problems.

1. It is not possible to inspect the test object that has rough surface like weld

2. There is a dead band so it is not possible to inspect the defect directly under the surface

3. It is hard to inspect the narrow part like grooves of gear wheel and joint of turbine

*Developing of the new soft probe that is fit flexibly

Japan Probe Co, Ltd developed the probe that has soft test surface.

At this time, we reconsider the structure of an electrode of conventional soft probe, and we developed the new model of soft probe that has original structure.

This probe is composed of composite element that has flexibility, matching layer and damper material.

This probe realizes following:

1. It fits to test object that has a rough surface like weld and uneven surface, so it is possible to conduct ultrasonic inspection with direct contact.

2. We improve SN ratio during transmission and reception of ultrasonic waves, so it is possible to detect a defect that exists directly under the surface because dead band of this probe is narrow.

3. Test surface of this probe is small and fits flexibly, so it is possible to inspect at narrow part with direct contact.

*Use of the new model of soft probe

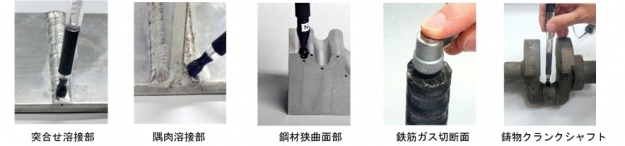

It is possible to inspect butt weld zone, fillet weld zone, casting, gas cut face, rough surface like a gear wheel, test objects that have uneven/narrow part with direct contact.

It is possible to applied to various industrial field, for example, iron and steel, architecture and civil engineering, electricity and chemical plant, shipbuilding, automobile.

It is expected that this probe will be applied to medical field like breast cancer screening.

*Utility Model: Registered utility model No. 3191253

*Sale start date: 5th January, 2015

Reception for free lending and sample test also start on same date.

*Pictures:

We lined up 4 types.

And you can choose frequency (1~10KHz), number of element (1 or 2), Diameter of the point of the probe (2~20mm), shape (L-Shaped and U-Shaped).

You can use this probe with commercially available ultrasonic flaw detector.

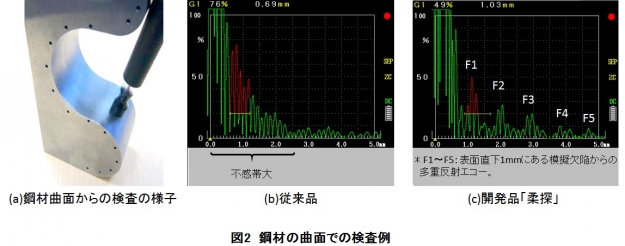

Fig.2 (a) shows inspection of a curved surface of a steel material.

Fig.2 (b) and (c) is the comparison of inspection results, and it shows that the new model of soft probe detects a simulation defect with diameter of 1.5mm, under 1mm from a surface.

*Explanation of the terms

1. soft probe: the probe that its test surface is composed of flexible materials. if the test object has rough surface and uneven part, test surface follows the test object. so you don't need to polish inspection part, and you can inspect with direct contact.

2. composite element: the element that is given flexibility by machining grooves on ceramics and saturation with resin.

3. matching layer: the layer that is enabled to transmit and receive ultrasonic waves efficiently.

4. Damper: the material that absorb transmitted ultrasonic waves and makes wavenumber less to widen a band.

5. SN ratio: the ratio of signal amount to noise amount. If the SN ratio is high, effect of noise in transmission is small, and if the SN ratio is low, effect of noise in transmission is big. high SN ratio is also referred to as "good SN ratio", and low SN ratio is also referred to as "bad SN ratio".